What Makes Cryogenic Deflashing Method a Cut Above The Rest?

Before the final inspection and packing, moulded rubber parts must undergo a finishing process to remove excess flashes. “FLASH” is an excess amount of rubber that oozes out between the two halves of a mould during the moulding of rubber parts.

The flash occurs in areas where different sections of the mould join together and are called the ‘parting line flash’. The remaining part of the mould flash traces around where the different sections of the mould join together.

Flashes cannot be avoided no matter what technique has been used to manufacture these rubber products. While manufacturing high-performance materials for growing markets like electronics and automotive, intricate finishes, consistency and strict tolerance must be met.

Importance of Cryogenic Deflashing

This is the only method that makes it possible to eradicate complex flash at the inner dimensions. Parts with a thin flash can be removed through cryogenic deflashing quickly. The traditional deflashing methods generally deliver a poor deflashing effect as it is done manually with the help of blades, scissors or knives. The manual trimming method has a high variability in quality and the production rate due to the geometry of the parts. Since the finish quality is not up to the mark, it leads to high rejection rates. Unevenly deflashed products when used can affect and damage the machine it is used in.

The Process of Cryogenic Deflashing

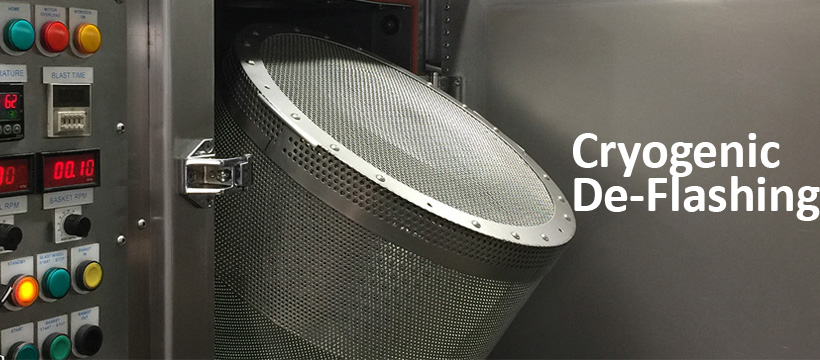

Cryogenic Deflashing is a combination of rapid rotation, nitrogen and plastic blast media is used to get rid of the flash in an extremely precise and economical way. The rubber parts are arranged in a perforated container which is then inserted in a blast enclosure.

The containers rotate and evenly expose all sides towards the blast media. The enclosure is insulated with firm polyurethane foam for stable temperatures. The liquid nitrogen decreases the temperature inside and freezes the flashing to make it fragile.

With the use of pure nitrogen with zero moisture the requirement of a dryer is eliminated. A fast-moving impeller shoots the polycarbonate pellets in the container. These high-speed pellets trim the inner as well as the outer diameter flashing neatly in a single operation. The effective lubricity and hardness lessens the impeller’s wear and increases its durability.

Parting- line flash thickness determines the capability of the system to finish the moulded part in concurrence with the cycle time and LIN consumption. A thicker flash is more difficult to get rid of and requires lengthier deflash cycle time which results in higher LIN consumption. The optimum parting-line flash thickness is 0.001” to 0.005”. Optimum finish quality and LIN consumption are based on the mould design and condition.

Advantages of Cryogenic Deflashing

Cryogenic deflashing offers numerous advantages over other traditional or manual deflashing methods:

● This process maintains an element of integrity and precision and ensures greater productivity.

● Due to this using a batch process, the cost of per piece is lesser as the number of parts processed in a specific time increases. This makes the manufacturing process economical and cost-efficient.

● Repairing or replacing a mould rises up the expenses bracket. In this method, the moulds can bede-flashed which extends their durability.

● It delivers consistent results in every lot.

● This technique is completely non-abrasive.

● The entire procedure is highly automated which eliminates the need of a human operator.

● This method eradicates the use of any toxic chemicals and is enclosed to a minimum sound which proves it to be environmental-friendly.

Harkesh Rubber uses cryogenic deflashing which is the most advanced deflashing process, unlike most of the other OEM’s. This method polishes the parts (typically O-Rings) and minimizes any sign of the flash or parting line delivering an efficient and precise product.

With this process, we ensure precision and fulfill our commitment of delivering a quality product. This technique not only improves the performance of the product but also saves the time and effort invested which eventually reduces the cost of production as well.