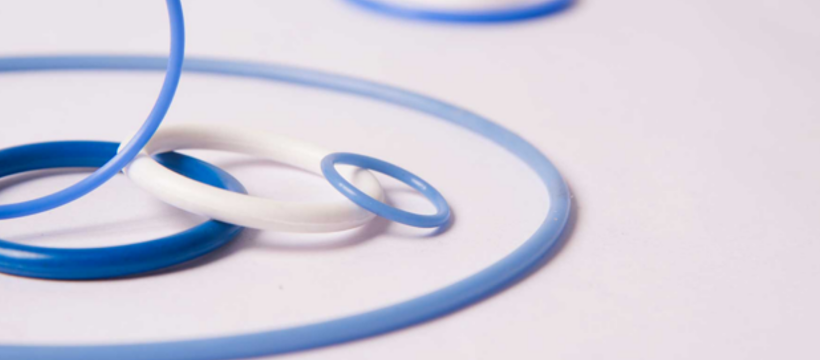

The Significance Of O-Rings For Sealing Solutions

Since the first one was registered in 1896, it won’t be wrong to say that o-rings were one of the oldest inventions! This ring-like designed loop helps in the prevention of gases or liquids. It is known to be one of the easiest precision mechanism objects ever manufactured and they continue to be the most widely used products for sealing solutions.

The production of o-rings requires carious manufacturing techniques like compression moulding, transfer moulding, extrusion, injection moulding or machining. As per the application requirements they can be made using different rubber materials. While designing o-rings a number of factors need to be kept in mind like the cost, quality, quantity, sealing pressure, application temperature, movement, chemical compatibility, lubrication, action and much more.

In some scenarios, o-rings are required to be exposed to tremendous heat or toxic chemicals. This is why different materials are used to make o-rings to fit the requirements depending on the application. Similarly, the o-ring sizes may vary according to the usage requirements.

O-rings are basically used to place into a groove for it to hold the air or fluid in place and then squeeze it between the two surfaces. When this action is performed, the pathway where the air or fluid is escaped from is blocked. The speciality of a rubber o-ring is its muscle-memory, which means it goes back to the original shape. This feature is what helps o-rings function with sealing under low or no pressure. When pressure is applied, the o-ring is squeezed in opposition to the wall of the groove which forces it to expand in the opposite direction. This technique helps o-rings perform the sealing function against the ends of the groove.

There are a number of industries that extensively use o-rings. Some of these are listed below:

1) Aerospace:

The aerospace industry is highly dependent on o-rings. They need to use o-rings with the design and material which provide flexibility to fulfil their demands. Extreme temperatures and radical fluctuations in temperatures are a few concerning conditions in the aerospace industry. The utilization of o-rings is done for hydraulic systems, landing gear systems, gas turbine engines, braking and many such purposes.

2) Automation:

The various automobile products are of different natures. They consist of gas and liquid, refrigerant gases and liquids and lubricant oils of various nature. Adding to these is the difference in temperatures. To these, we must add the dissimilarities in the different temperatures that the fluids are put to work in along with the speed that can vary the exercise conditions. O-rings are of great use for the braking circuits, lubricant circuits and the air-conditioning systems.

3) Oil & Gas:

he oil and gas industry portray extreme conditions which need the o-rings to operate in these conditions accordingly. The mechanical, fluid phase and thermo-chemical conditions need to be accommodated in order to maintain the required integrity of the o-rings. They are required to be resistant to sour gas, explosive decompression, aggressive chemicals and extreme temperatures.

4) Chemical Processing:

The applications in chemical processing industries are often critical. Besides the wide chemical resistance in o-rings, the resistance to the difference in changing temperature also holds great importance. They requisite to have the ability to eliminate cold flow and drift and are able to pass over the portholes without any damage.

5) Food & Beverage:

The food and beverage industries require o-rings to be able to withstand the thermal and chemical environments that are present in the equipment. They also need to hold back any unknown or unwanted contaminants in the process. Since they may come into contact with consumption items, these o-rings need to be capable of remaining hygienic and receive an effective bacterial treatment while they still maintain their physical properties.

Sealing solutions among all kinds of industries require o-rings in various forms for different applications as per their custom requirements. We manufacture o-rings that are capable to resist high temperatures and pressures that do not bulge and are flexible and suitable for all kinds of environments.