SEALING

SOLUTIONS IN

THE USA

At Harkesh Rubber, we don’t just supply rubber components. We engineer sealing solutions that keep America’s industries running smoothly. From Rubber Diaphragms to O-rings and custom gaskets, our products are designed to perform in the real-world conditions you face every day.

With over 35 years of specialized manufacturing experience and a deep understanding of critical applications across automotive, aerospace, oil & gas, water treatment and more – we deliver what others promise: leak-proof performance, unmatched durability, and consistent quality from prototype to production.

Whether you’re solving a recurring seal failure, improving an existing system, or developing a next-gen product, Harkesh Rubber is your trusted performance partner in the USA.

Our Range of Rubber Sealing Products

We offer a wide range of high-quality premium sealing components, engineered for critical applications across U.S. industries.

Rubber Diaphragms

Built for precision and reliability, our rubber diaphragms are designed to handle pressure fluctuations, aggressive media, and demanding cycles without compromise.

Whether you’re manufacturing automotive actuators, operating oil & gas control systems, or assembling medical-grade equipment, our diaphragms offer consistent performance under tough conditions. Available in EPDM, Nitrile, Silicone, and FKM, these diaphragms offer excellent resistance to heat, chemicals, and abrasion – tested for long-term integrity.

If you have a unique specification or compound requirement, our engineers will help you create a tailored solution.

Applications – Automotive, Oil & Gas, Water Systems, Medical Equipment

Support – Custom formulations and tailored specifications

Rubber to Metal Bonded Parts

Engineered for exceptional strength and durability, our rubber-to-metal bonded components excel in high-pressure applications. Using advanced bonding processes, we ensure permanent adhesion between rubber and metal substrates so components can withstand vibration, impact, and pressure over long service lives.

Available in Nitrile, Natural Rubber, Neoprene, EPDM, and Silicone, they deliver high load-bearing capacity and consistent performance even under harsh conditions.

Applications: Automotive suspension systems, aerospace mounts, heavy industrial machinery

Benefits: Maximum adhesion, long service life

Large Size Rubber Components

Designed for scale, our large-format components provide robust sealing under pressure and in extreme temperatures. Using custom molds and high-resilience elastomers, we manufacture oversized seals and parts capable of handling extreme pressures and temperatures.

With weather and chemical resistance, tailored geometries, and proven material integrity, these components provide reliable sealing for the toughest applications.

Applications: Oil & Gas, marine systems, power plants, heavy machinery

Advantages: Custom molding, high-resilience elastomers, weather & temperature resistance.

Customized Rubber Components

Tailored to your exact specifications, from geometry to compound, we provide precision custom sealing components for specialized applications. We work closely with OEMs, R&D teams, and specialty equipment manufacturers to create sealing solutions that solve unique challenges.

From rapid prototyping to high-volume production, every stage is handled in-house for consistent quality. Whether you need special material formulations, tight tolerances, or unusual part configurations, our engineering team ensures precision, repeatability, and cost-effectiveness.

Industries served: OEMs, R&D teams, specialty equipment manufacturers

Support: From prototyping to mass production

O Rings

Our precision-engineered O-rings are designed for leakproof sealing across critical systems. Manufactured to strict tolerances, they offer dependable performance across industries where failure isn’t an option.

Available in NBR, Viton, EPDM, and Silicone, these O-rings can be tailored for aerospace systems, food-grade equipment, hydraulics, and medical devices. They combine high-pressure resistance, chemical compatibility, and temperature stability for long-lasting service.

Materials – NBR, Viton, EPDM, Silicone

Applications – Aerospace, food-grade systems, hydraulic equipment

Features – High-pressure, chemical, and temperature resistance

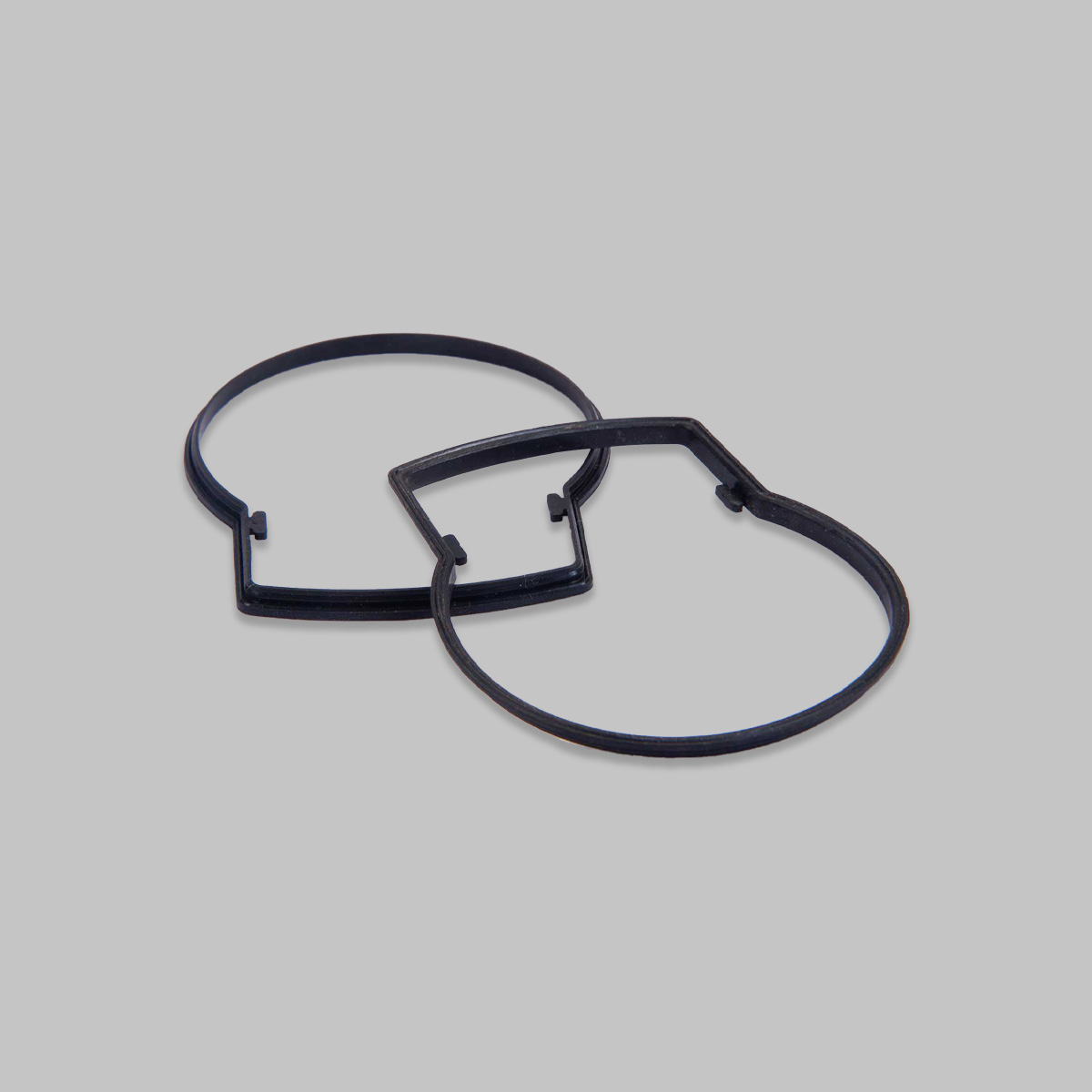

Rubber Gaskets

Designed for reliable sealing under compression, vibration, and thermal stress, our rubber gaskets provide secure sealing where it matters most. We manufacture both die-cut and molded gaskets in a variety of thicknesses and elastomers to match your application.

Ideal for automotive assemblies, HVAC systems, electronics, and water treatment facilities, these gaskets resist aging, ozone, and fluid exposure. Our customization options allow you to specify material grade, thickness, and cut style for optimal performance.

Applications: Automotive, HVAC, electronics, water treatment

Customization: Thickness, material-grade, die-cut or molded

Butterfly Seals

Our Butterfly Seals ensure tight shut-off and long-lasting sealing performance that stands the test of time – especially in demanding valve systems. Designed for reliability, they resist chemical corrosion, high temperatures, and mechanical wear to maintain effective flow control.

Each seal is tested to deliver consistent performance and extended service life. They are widely used in power generation, chemical processing, and water treatment systems where durability under aggressive media and high-cycle conditions is essential.

Applications: Power generation, chemical processing, water treatment

Resilience: Resistant to chemical corrosion, heat, and mechanical wear

Wire Seals

Engineered for air tight and water tight protection in sensitive systems. They maintain performance under pressure, vibration, and extreme conditions to safeguard electrical connections and enclosures.

Commonly used in automotive electronics, aerospace, telecommunications, and electrical enclosures, our wire seals combine high-durability materials with precision manufacturing.

They resist moisture, dust, and environmental stress for dependable long-term protection.

Applications: Automotive electronics, aerospace, electrical enclosures

Performance: Sealing under pressure, vibration, and extreme conditions

Why Choose Harkesh Rubber for Rubber Sealing Solutions in the USA?

In high-stakes industries, sealing failures aren’t just costly, they’re dangerous. That’s why engineers, procurement teams, and OEMs across the USA trust us for solutions that work the first time – and every time.

Our Advantage

- 35+ years of proven manufacturing expertise

- Complete range of standard and custom components

- Top-tier elastomers tested for long-term performance and safety

- Precision processes for rubber-metal bonding, molding, and prototyping

- Advanced R&D and in-house quality control labs

- Reliable global supply chain with fast delivery across USA, Asia, Europe, and the Middle East

- Accreditation of ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, and IATF 16949:2016 standards.

From small batch custom runs to high-volume orders, we scale seamlessly to meet your supply and performance needs – without compromise.

Industries We Serve in the USA

Our decades-long engineered rubber solutions are trusted across industries where precision, durability, and safety are paramount:

Automotive & Electric Vehicles

Aerospace & Aviation

Oil & Gas

Power Generation

Water Treatment & Filtration

Food & Beverage Processing

Medical & Healthcare Equipment

Electronics & Consumer Goods

Oil & Gas

Get the Best Rubber Sealing Solutions in the USA

When your equipment depends on reliable sealing, Harkesh Rubber delivers. Our expertise, technology, and commitment to quality make us the preferred rubber sealing partner for industries across the United States.

Contact us today for a consultation or custom quote

Engineered in India. Trusted Worldwide. Delivered Across the USA.