Customized Rubber Components

- Home

- Customized Rubber Components

Our Products

Essential

Materials for You

Customized Rubber Components

About

Apart from normal rubber applications, there are numerous engineering sectors where rubber is employed for flexibility, cushioning, leakage prevention, and a variety of other purposes. When compared to other metal processes, rubber is a relatively simple and cost-effective solution, so designers frequently build non-standard rubber components to match their needs.

Rubber Concept can create practically any design, any material rubber component based on an application, drawing, or sample.

Our production process is a combination of scientific reasoning and tactful acumen, thus, our best engineers are involved right from the curation of material composition to the successful in – house testing and validation.

As a result, one amongst the many milestones has been achieving a dimensional tolerance of +/- 0.001 inches and playing as one of the dominant suppliers of Gas Regulator parts in enormous quantities of and not limited to 100,000 per month.

We have reverse engineered many customized seals with highly Complex designs and material specifications for our clients example includes Aerospace applications.

Salient Features

Custom Rubber Components

Every application has its own set of challenges, and at Harkesh Rubber LLP, we focus strongly on creating custom rubber components that match those unique requirements. Beyond custom sizing, many projects call for special shapes, material blends, or intricate design features. Our engineering team has extensive experience in reverse-engineering complex rubber parts and developing them with precise material specifications to deliver consistent performance.

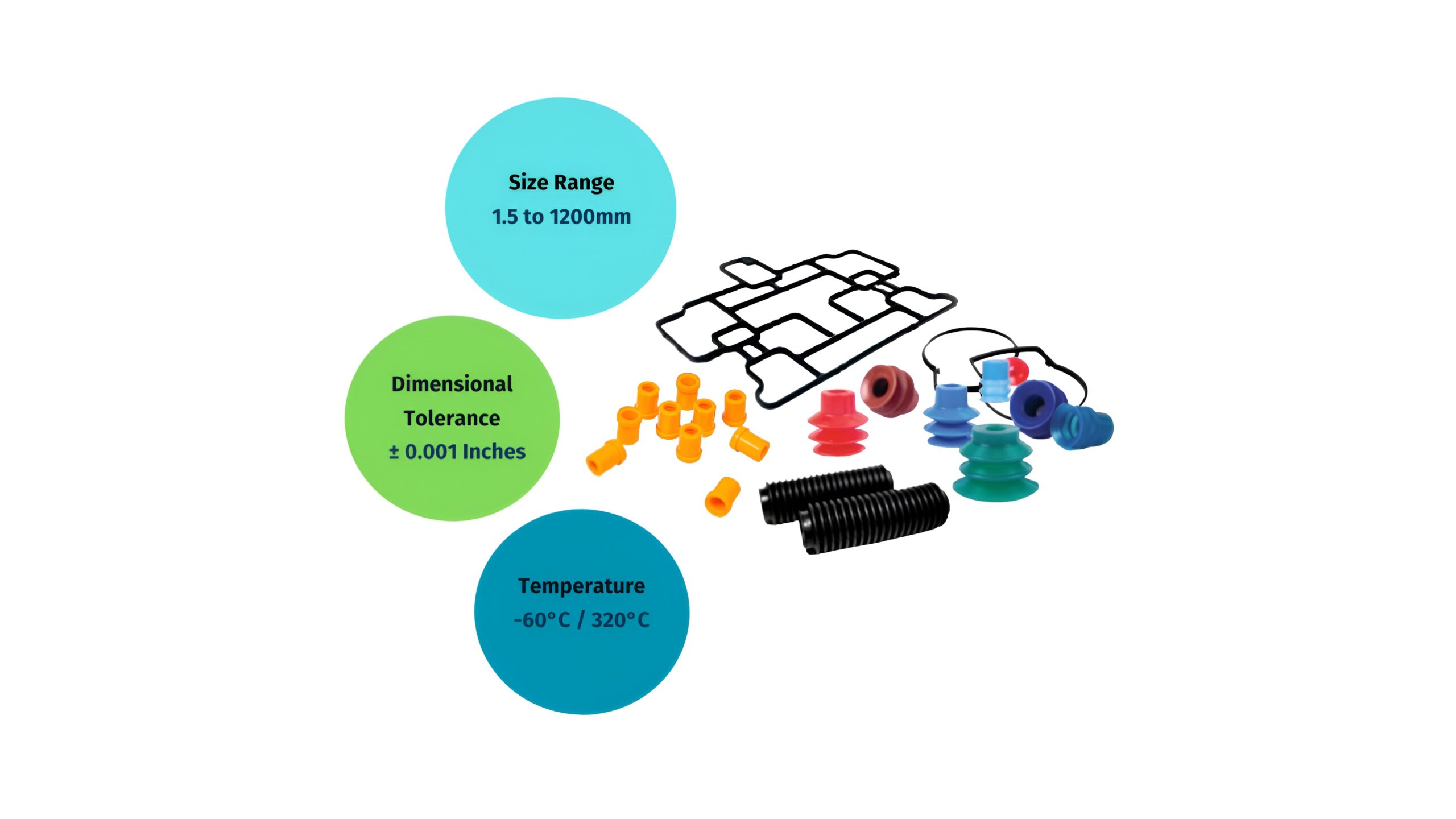

Salient Features

- Expertise in reverse engineering complex and customized rubber parts

- Size range from 1.5 mm to 1200 mm for diverse applications

- Temperature resistance from –60°C to +320°C (material dependent)

- REACH, ROHS, EN 549, WRAS approved compounds

- Flash levels less than 0.10 mm for clean and precise finishing

Custom Rubber Components

Every application has its own set of challenges, and at Harkesh Rubber LLP, we focus strongly on creating custom rubber components that match those unique requirements. Beyond custom sizing, many projects call for special shapes, material blends, or intricate design features. Our engineering team has extensive experience in reverse-engineering complex rubber parts and developing them with precise material specifications to deliver consistent performance.

Salient Features

- Expertise in reverse engineering complex and customized rubber parts

- Size range from 1.5 mm to 1200 mm for diverse applications

- Temperature resistance from –60°C to +320°C (material dependent)

- REACH, ROHS, EN 549, WRAS approved compounds

- Flash levels less than 0.10 mm for clean and precise finishing

Custom-Engineered Rubber Components

We work closely with clients to design and produce custom rubber seals, custom gaskets, and specialty components tailored to their operating conditions. Whether you need tight tolerances, specific hardness levels, or proven resistance to pressure, temperature, or chemicals, we can create custom-made solutions that integrate seamlessly with your existing equipment.

- Precision, Performance, and Material Flexibility

Precision, Performance, and Material Flexibility

Our manufacturing capabilities allow us to produce custom made rubber gaskets and components ranging from miniature sizes to large formats up to 1200 mm. The materials used are selected based on performance requirements, giving you dependable sealing across a wide temperature range and exposure environments.

-

What types of custom rubber components do you manufacture?

We produce custom rubber seals, custom gaskets, and specialized components designed for demanding industrial applications.

-

Can you reverse-engineer a component if we only provide a sample?

Yes. We specialize in reverse engineering and can recreate complex rubber parts with accurate material and dimensional matches.

-

What size range can you manufacture?

We can produce components from 1.5 mm up to 1200 mm in diameter.

-

Are the materials used certified?

All compounds are REACH, ROHS, EN 549, and WRAS-approved.

-

Can you create custom rubber gaskets for high-temperature applications?

Yes. Depending on the material selected, custom gaskets can withstand temperatures from –60°C to +320°C.